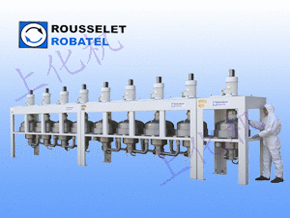

French multistage centrifugal extractor

Robatel's centrifugal extractor offers the following advantages over traditional liquid-liquid extraction equipment:

→ Short residence time, less material retention.

→ High separation factor, high liquid phase separation efficiency.

→ Frequent shutdown is needed to quickly reach the balance of operation, which is conducive to intermittent operation.

→ simple structure, large processing capacity.

→ Solid structure, multi-stage drum (LX320 and LX360 more than 5 levels; LX520 more than 7 levels; LX570 more than 6).

→ Extraction efficiency (in theoretical terms) is not affected by the total and relative flow rates of the two liquid phases. Each mechanical stage is essentially equivalent to a theoretical stage.

→ With stable hydraulic pressure, thus simplifying operation and reducing the implementation of fine tuning to liquid inlet and outlet pressure.

→ Low installation cost (non-special base; Drive motor drive multiple extraction stage).

→ Accessories are simplified.

Structural features:

These types of extractors are mounted on cast-iron frames with earthquake-resistant supports, eliminating the need for a special base.

The drum is supported by a stainless steel hub mounted on a high-strength stainless steel shaft with roller bearings.

There are air-tight housing around the drum, which can realize the operation of the machine under the protection of inert gas. High strength stainless steel shaft equipped with sealing cover.

The LX320 and LX520 series are available with a gravity drain port or one or two turbo pumps for drain.

In the LX360 and LX570 series, the light phase is discharged by the turbo pump, and the heavy phase is discharged by the turbo pump or gravity.

All parts in contact with the liquid to be treated are 316L stainless steel, 18 chromium, 10 niobium, 2.5 molybdenum (other materials can be used if necessary)

All models of the drum through the V-shaped belt connected to the electronic motor, can be replaced on the V-shaped belt pulley to adjust the speed.

The LX520 and LX570 series are available with a hydraulic coupler to reduce motor inrush, or standard motors are optional.

If no hydraulic coupler is provided, the following equipment can be used in conjunction with the standard motor:

Electronic soft starter

AC frequency conversion drive, to achieve a variety of speed

Working principle:

The loaded solution initially containing one or more solutes (the heavy phase in the schematic) and another immiscible solvent of different density (the light phase in the schematic) flow in the opposite direction in the extractor drum. Subsequent mixing and separation operations transfer the solute from the heavy phase to the light liquid.

Each mechanical stage corresponds roughly to a theoretical stage and consists of:

The mixing chamber in which a central drum is connected to the housing and a fixed stirring dish on the central drum mixes the two liquid phases.

The relatively high velocity between the stationary stirring dish and the rotating wall of the mixing chamber produces a very fine emulsion with low interfacial tension, which speeds up the mass transfer process and rapidly achieves an equilibrium solution concentration even with a high flow ratio.

The mixing dish and the inlet and outlet pipes of the mixing chamber function as pumps to draw the two liquids from adjacent stages and transfer the emulsion to:

The sedimentation chamber, in which centrifugal force separates two previously mixed liquids completely. A pair of overflow baffles (B and C) stabilize the position of the phase interface so that it is not affected by the liquid flow rate.

The heavy liquid overflow baffle (B) is replaceable and its internal diameter is a function of the liquid density ratio to improve the performance of the extractor.

In addition, each set of overflow baffles is suitable for a variety of liquid density ratios (e.g., from 1.20 to 1.35), thereby minimizing the number of adjustments required.

The two liquid phases are fed into the extractor by a pipe on the housing. Therefore, no mechanical seal is required.

The thickened solvent (extract) and diluted liquid (extract) are discharged from the extractor either by gravity discharge or by a centripetal turbine. The centripetal turbine is capable of generating the pressure required to discharge the material, allowing multiple operations to be carried out by connecting multiple extractors.

When the drum stops, the liquid is expelled through a pipe located at the bottom of the housing.

LX320 | LX360 | LX520 | LX570 | ||||||||||

model | LX323 | LX324 | LX325 | LX363 | LX364 | LX365 | LX524 | LX525 | LX526 | LX527 | LX574 | LX575 | LX576 |

series | 3 | 4 | 5 | 3 | 4 | 5 | 4 | 5 | 6 | 7 | 4 | 5 | 6 |

Drum diameter mm | 320 | 320 | 320 | 360 | 360 | 360 | 517 | 517 | 517 | 517 | 570 | 570 | 570 |

The drum capacity L | 11 | 10.2 | 9.3 | 14.6 | 13.6 | 12.6 | 57 | 54 | 52 | 49 | 74 | 70 | 67 |

Maximum speed r/min | 3200 | 3200 | 3200 | 3000 | 3000 | 3000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

The motor power kW | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 |

The net weight kg | 280 | 290 | 300 | 300 | 310 | 320 | 1020 | 1040 | 1060 | 1080 | 1100 | 1130 | 1160 |

Maximum flow L/h | 1800 | 1500 | 1300 | 2100 | 1800 | 1500 | 6000 | 5000 | 4500 | 3500 | 8000 | 7000 | 6000 |

Overall dimensions mm | 1050 X 590 X 760 | 1550 X 840X 1100 | |||||||||||

The flow rate per hour is a function of the viscosity, emulsification, and concentration-flow ratio of the liquid. The above values correspond to products with low emulsification, density ratio of about 1.25, and flow ratio of 1